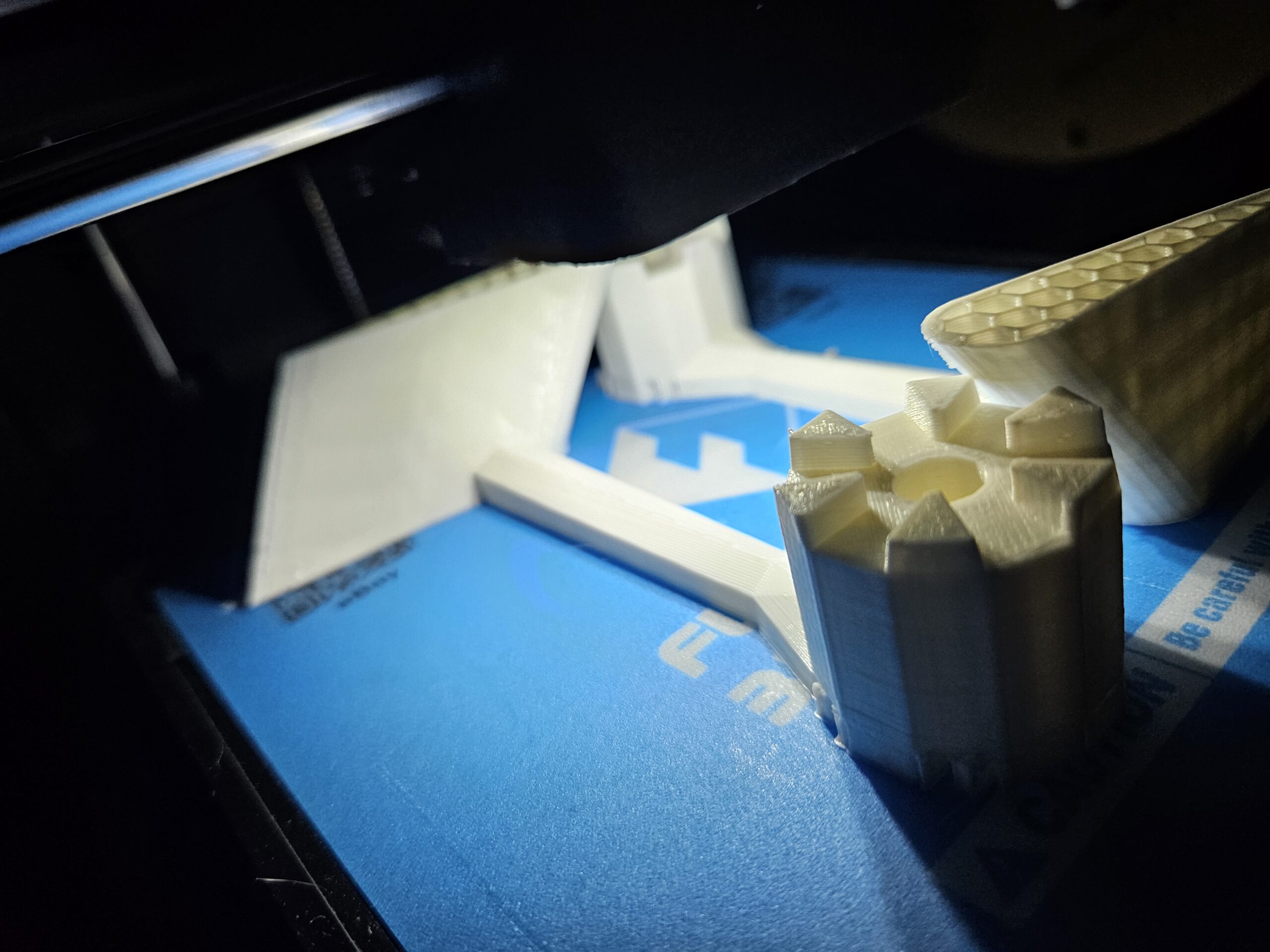

Additive Manufacturing, commonly known as 3D printing, has emerged as a revolutionary force in modern industry. Unlike traditional subtractive manufacturing methods, 3D printing builds objects layer by layer, offering unparalleled flexibility, efficiency, and creative possibilities. From aerospace to healthcare, the applications of additive manufacturing are diverse and transformative, declaring a new era in the way we conceive, design, and produce goods. One of the key advantages of additive manufacturing is its ability to produce highly customized and complex designs. Traditional manufacturing processes often struggle with intricate geometries, but 3D printing excels in creating structures that were once deemed impossible. This opens up new possibilities in product design, allowing for the production of components with optimized shapes and functionalities tailored to specific needs. In the aerospace and automotive industries, additive manufacturing has become a game-changer. The ability to create lightweight and structurally optimized components has led to improved fuel efficiency in vehicles and aircraft. Additionally, 3D printing allows for the rapid prototyping of parts, reducing lead times in the development of new models and enhancing the overall efficiency of the manufacturing process. The impact of additive manufacturing on healthcare is nothing short of revolutionary. Customized implants, prosthetics, and even patient-specific organs are now a reality. Surgeons can utilize 3D-printed models to plan and practice complex surgeries, resulting in better outcomes for patients. The ability to tailor medical solutions to individual needs is transforming the landscape of healthcare, offering new hope to those in need of specialized treatments. Additive manufacturing plays a crucial role in building resilient supply chains. Traditional manufacturing often relies on centralized production facilities, making supply chains vulnerable to disruptions. 3D printing allows for distributed manufacturing, enabling the production of parts and components closer to the point of use. This not only reduces transportation costs but also enhances the adaptability and resilience of supply chains in the face of unforeseen challenges. In an era where sustainability is a paramount concern, additive manufacturing stands out for its material efficiency. Traditional manufacturing processes often result in significant material waste, but 3D printing generates minimal waste by adding material only where needed. The ability to use recycled materials further contributes to a more sustainable approach to production, aligning with the global push for environmentally conscious practices. Additive manufacturing is democratizing the manufacturing process. Small businesses, startups, and individual innovators can harness the power of 3D printing to bring their ideas to life without the need for large-scale manufacturing facilities. This democratization fosters a culture of innovation, enabling a wide range of industries to benefit from the creative and economic possibilities offered by Additive Manufacturing. In conclusion, Additive manufacturing is reshaping the landscape of modern industry, offering unparalleled opportunities for customization, efficiency, and sustainability. From healthcare breakthroughs to aerospace innovations, the applications of 3D printing are vast and transformative. As the technology continues to evolve, it holds the potential to redefine the way we approach production, unlocking new possibilities and pushing the boundaries of what is achievable in manufacturing and design. The era of additive manufacturing has dawned, and its impact is set to reverberate across industries for years to come.

Leave a Reply